10 Sep Precast Concrete Exterior Systems – Versatility and Benefits

Welcome to our latest exploration into the dynamic world of construction materials. Today, we’re focusing on a material that’s been gaining significant traction in the industry due to its myriad advantages: Precast Concrete Exterior Systems. These systems are not only time-efficient and safe but also score high on durability, low maintenance, sustainability, and versatility. Whether you’re an architect, builder, or homeowner, understanding the benefits of precast concrete exterior systems could revolutionize your next project. Let’s delve deeper into each of these benefits and understand why precast concrete is becoming the go-to material for savvy industry professionals.

Time-Efficiency with Precast Concrete Exterior Systems

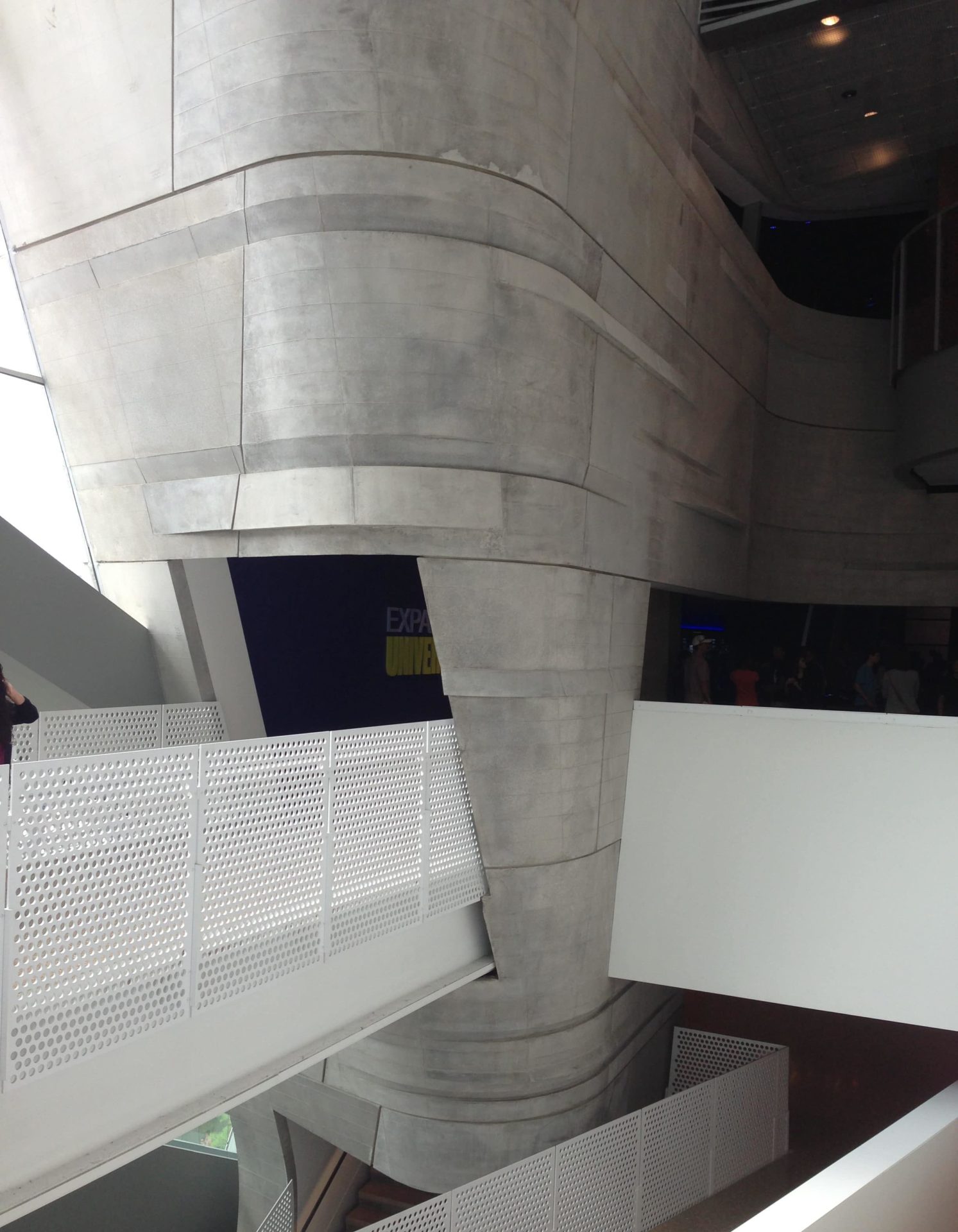

Perot Museum, Dallas TX

One of the most significant advantages of precast concrete exterior systems is their time-efficiency. Unlike traditional construction methods that involve pouring concrete on-site, precast concrete is produced in a controlled factory environment. This controlled setting allows for a streamlined manufacturing process, which significantly reduces the time required to produce each piece.

The ability to manufacture these components in advance means that they’re ready to be installed as soon as the site preparation is complete. This eliminates the waiting period typically associated with on-site concrete pouring and curing. As a result, construction projects using precast concrete exterior systems can be completed in a fraction of the time compared to those using traditional methods.

Enhanced Safety with Precast Concrete

In addition to time efficiency, the production of precast concrete exterior systems in a controlled factory environment also enhances the safety of workers. Traditional on-site construction presents numerous hazards, including falls, contact with heavy machinery, and exposure to harmful substances.

By contrast, the factory production of precast concrete components minimizes these risks. Workers are able to operate in a stable, regulated environment, away from the unpredictability of a construction site. Moreover, because the pieces are manufactured off-site and then transported, there’s less need for heavy machinery at the construction site, further reducing potential safety risks.

Another significant safety benefit comes from the development of more unitized systems where the glazing is pre-installed in the precast panels. This innovative approach eliminates the need for workers to hang off buildings installing windows, a task that traditionally carries a high risk of falls and injuries. Instead, these pre-glazed units can be safely and efficiently installed directly from the ground or with minimal elevation, significantly enhancing the overall safety of the installation process. This not only protects the workers but also improves the timeliness and reliability of construction projects.

Unmatched Durability of Precast Concrete Systems

Navy League, Arlington, VA

A primary advantage of precast concrete exterior systems is their exceptional durability. These systems are designed to stand the test of time, providing a robust and resilient solution for construction projects of all sizes. Unlike other materials that may deteriorate or lose their structural integrity over time, precast concrete maintains its strength and stability, even in the face of adverse weather conditions and heavy use.

The durability of precast concrete is largely due to its virtually air and watertight exterior surface. This characteristic makes it resistant to elements such as moisture and temperature fluctuations that can cause damage to other building materials. As a result, structures built with precast concrete are less likely to require costly repairs or replacements down the line, making it a cost-effective choice for long-term projects.

Low-Maintenance Benefits of Precast Concrete

In addition to its durability, precast concrete also boasts low maintenance requirements. The impenetrable exterior of a precast building solution contributes to a long service life due to its low-maintenance surfaces. Unlike other materials, which may need regular treatments or upkeep to maintain their appearance and performance, precast concrete requires minimal maintenance.

This low-maintenance nature not only saves time and effort but also significantly reduces the ongoing costs associated with building upkeep. This makes precast concrete an attractive option for both developers and owners alike. It’s an especially appealing choice for large-scale projects or structures in harsh environments and extreme weather, where maintenance tasks can be particularly challenging and costly.

Sustainability: The Green Choice

In an era where sustainability is a paramount concern, precast concrete exterior systems shine as an environmentally friendly choice. Precast concrete is manufactured using natural materials like Type1L cement, sand and crushed aggregates, which are abundant and often locally sourced, reducing the environmental impact associated with transportation. Type 1L cement’s limestone content results in a 10% reduction in its carbon footprint. Furthermore, the production process of precast concrete involves low energy consumption compared to other building materials, further enhancing its green credentials.

Moreover, the durability and long lifespan of precast concrete contribute to its sustainability. Because it doesn’t need to be replaced as frequently as some other materials, there’s less waste generated over time. This makes precast concrete not only a durable and cost-effective choice but also a responsible one for those looking to minimize their environmental footprint.

St. Edwards University

Noteworthy in the realm of sustainability is GATE Precast, a company that has taken significant strides towards environmental responsibility. GATE Precast boasts both product-specific and facility-specific Environmental Product Declarations (EPDs). EPDs are independently verified documents that report environmental data of products based on life cycle assessment (LCA) and other relevant information. They cover aspects from raw material extraction through processing, manufacture, distribution, use, repair, maintenance, and disposal or recycling. Very few precasters have this level of commitment to transparency and sustainable practices. This allows architects, engineers, and builders to make more informed choices about the materials they use, contributing to the overall sustainability of their projects. GATE Precast’s dedication to such detailed environmental reporting sets them apart in the industry and further underscores the potential for precast concrete in sustainable construction.

Versatility: Tailored to Your Needs

Precast concrete’s benefits extend beyond its sustainability. It’s also incredibly versatile, capable of being molded into virtually any shape, color, and texture. This flexibility allows architects and designers to tailor the material to meet specific aesthetic requirements, making it suitable for a wide variety of construction projects.

Whether you’re aiming for a modern, sleek design or a more traditional, rustic look, precast concrete can be adapted to fit your vision. It can mimic other materials like brick or stone, providing the desired aesthetic without compromising on durability or maintenance. This versatility opens up a world of design possibilities, enabling the creation of unique, visually appealing structures that stand out from the crowd.

In conclusion, Precast Concrete Exterior Systems present a compelling case for their use in any construction project. Their time-efficiency and inherent safety during manufacturing afford a significant advantage over traditional construction methods. The durability and low maintenance features guarantee longevity, while their sustainability and versatility ensure a minimal environmental footprint without compromising on aesthetic appeal. As we continue to strive for efficient, durable, and healthy building solutions, precast concrete stands out as a frontrunner. For those seeking a robust, reliable, and flexible construction material, precast concrete exterior systems are a choice well worth considering and GateStone is one of the most versatile exterior systems on the market today.