Emory Musculoskeletal Institute

Emory Musculoskeletal Institute

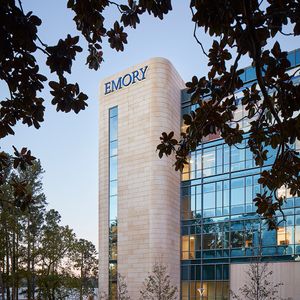

The guiding principle throughout the design and planning of Emory Healthcare’s 180,000 SF, 6-story Musculoskeletal Institute was to use building form to communicate the building’s purpose. The design of the facility reflects the Institute’s goal of restoring fluidity of motion to its patients.

The exterior façade features a prefabricated concrete solution with soft curved walls and corners that were designed to reflect the fluidity concept. An innovative panelization scheme was developed to reflect the structure of bones. Custom formliner patterns were used in the fabrication process of vertical elements that create a variation in the sharpness of the exterior and change its appearance throughout the day. GateStone’s randomness in coloring is achieved with multiple finishes and textures. More than half of the precast concrete panels were given a simulated limestone finish while the remaining panels were treated with medium- and light-abrasive blast finishes.

“Precast played an important role in defining the owner's goals by enhancing the concept of movement, bone structure, and encasing the building in a product that supports Emory’s commitment to the environment. Precast also allowed the design team to create an animated and flexible exterior and provided a solid design.”

- Steven Rodgers

Sr. Construction Administrator, HKS

The owner wanted the building to exemplify excellence and innovation and include sustainable features that would meet LEED Gold certification standards. To achieve the vision, the design features several curved precast concrete panels, including some that span more than 11' wide. The curved panels provide fluidity to the building, mimicking human anatomy. The panels combine perfectly with the electrified glass system on the south face of the building. Taken together, the precast concrete panels and glass provide an extremely energy-efficient southern exposed façade that boosts the facility's overall energy performance.

Precast concrete was the optimal solution for the institute because of its durability, ease of installation, as well as its flexibility and capability to provide the desired texture, depth, and massing. Because of its sustainable qualities, precast concrete also contributed to the institute's achievement of LEED Gold certification.

"Precast concrete was chosen for its panelized qualities, ability to shape the building, and textural qualities that support the design aesthetic. It was also chosen for its economic qualities as a building enclosure system and ease of construction."

- Bill Leggett, AIA, CDT

Sr. Project Manager and Principal, HKS

AWARDS

- (2024) PCI Design Awards: Best Healthcare/Medical Building

- (2022) World Architecture Festival Finalist, Completed Buildings: Health

VIDEOS

LOCATION

Alpharetta, GA

ARCHITECT

HKS